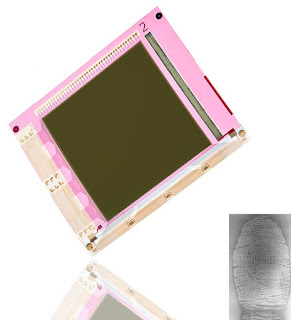

FlexEnable (used to be Plastic Logic) and ISORG reveal the world’s first large area flexible fingerprint sensor on plastic designed for biometric applications. With an 8.6 cm x 8.6 cm active area, 84µm pitch (78µm pixel size with 6µm spacing) and 1024 x 1024 = 1048576 pixel resolution, the flexible sensor is 0.3 mm thick and can operate in visible and NIR up to wavelengths of 900 nm. Other that fingerprint, the technology is also capable of measuring the configuration of veins in the fingers, providing additional security versus that of a surface fingerprint alone.

This new sensor is made by deposition of organic printed photodetectors (OPD) by ISORG onto a plastic organic thin-film transistor (OTFT) backplane, developed by FlexEnable. The large label-thin sensing area can be applied to almost any surface – and even wrapped around the objects in our daily lives that we typically come into contact with – such as a car steering wheel that recognises the driver as soon as the wheel is touched, or a credit card with integrated biometric detection.

Chuck Milligan, CEO of FlexEnable, said: “FlexEnable’s ground-breaking flexible electronics technology in combination with ISORG’s unrivalled expertise in OPDs and large area image sensors brings game-changing capabilities for biometric detection that can be applied to almost any surface – anything from door handles to wrists. For example, imagine a mobile device whose surface or edges know who is holding or touching the device. Such capabilities are viable because of the flexibility, thinness, and much lower cost per unit area compared to silicon area sensors.“

Jean-Yves Gomez, CEO of ISORG, said: “This break-through development will spark the creation of next-generation products in biometrics. No other solution can offer large area sensing as well as finger print and veins recognition while being flexible, light and robust. Moreover, our team is able to provide reference design as well as image improvement algorithms and illumination solutions to ease the sensor integration into new applications.”

What about robustness, lifetime, lag, noise, speed readout and other drawbacks concerning organic devices? I am afraid that this is only an additional commercial announcement based on a single prototype sample.

ReplyDeleteStill one commercial announcement from start-ups.... No information available regarding lifetime (organic technology never demonstrated capability for long life time operation vs semiconductor), current consumption for illumination (killing for portable devices), cost (high resolution obtained by photolithography not printed solutions + additional system cost for illumination & signal processing IC)and performance (biometrics requires 50um resolution)

ReplyDelete